X-Mid Pro 2

Pinnacle of Superlight Tent Design

The X-Mid Pro 2 combines our maximally weight efficient and stormworthy X-Mid geometry with Dyneema® fabrics and a singlewall design to create a tent that is both incredibly light and incredibly capable. It weighs as little as 17.9 oz (509 g) while also bringing unprecedented stormworthyness, simplicity, spaciousness, and build quality to the super ultralight tent niche.

SPACIOUS

Until the X-Mid Pro 2, if you wanted a 2P tent for a little over 1 lbs you had to settle for something cramped, delicate, and/or lacking in weather protection.

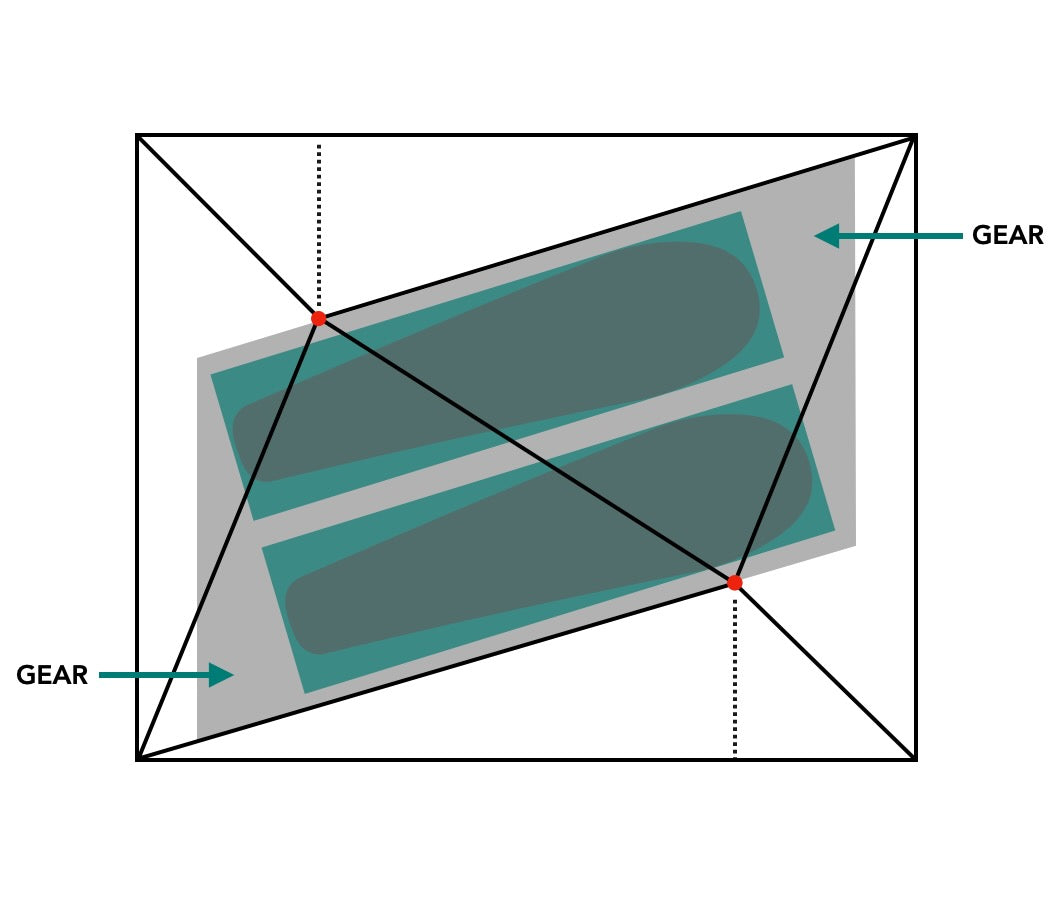

The X-Mid Pro 2 changes that. It provides a spacious interior for two adults with a generous 90″ floor length, ample 46" width, steep end walls to maximize useable length, and best-in-class headroom enabled by the unique geometry with a diagonal ridgeline and opposite diagonal floor. It fits hikers up to 6’4″ (dual occupancy) or 7’0″ (solo occupancy).

Also generous are the dual 11.6 sq ft vestibules which are large, tall, and conveniently place the main area beside the door instead of blocking it.

Want it even more spacious? Check out the X-Mid Pro 2+.

STORMWORTHY

The stormworthiness of the X-Mid Pro 2 is excellent thanks to the extremely strong Dyneema fabric combined with the high performance X-Mid shape. The X-Mid has the ideal shape for wind and snow because the geometry gives all of the panels slopes that are consistent and moderate. There are no horizontal roof panels to catch snow, nor vertical side panels to catch wind. The tent pitches solidly with just 4 stakes, while peak and side panel guyouts can be added along with 8 extra stake points around the base if conditions warrant.

More than just surviving, the X-Mid Pro 2 keeps you comfortable in tough conditions with it's protected pitch (keeps the floor dry during setup in the rain), protected doorways (keeps the rain out even when open), dual peak vents which minimize condensation, and full coverage fly that can extend low to the ground to block rain splatter and drafts yet can be lifted higher for increased ventilation. Competing tents trim away the bottom of the fly to save weight but this leaves you more exposed to drafts and rain splatter. The X-Mid Pro 2 further enhances comfort in tough weather with its large interior space, and generous vestibules.

Backpacking Light

Highly Recommended

"If you want the highest-quality and best-performing ultralight shelter on the market, the X-Mid Pro should top your list."

Backpacker Magazine

A Titan of Featherweight Design

"Simpler than just about any other trekking-pole tent. It’s hard to beat the simple but effective design."

The Trek

Simply the Best

"Simply the best tent...an impenetrable bunker, super high quality, easy to setup. We couldn’t have been more pleased."

Bikepacking.com

Gear of the Year

Durston’s lofty claims, especially compared to some other great shelters, are surprisingly valid...it proved to be outstanding in its class.

Adventure Alan

Our Favourite Super Ultralight Tent

"No other tent on the market gives you this much livable area for so little weight....an incredible tent design"

Backwoods Pursuit

An Absolute Gem

"Deflects wind, rain, and even snow with ease. Extreme attention to detail make it a joy to set up. I’m a HUGE fan."

USER FRIENDLY

The X-Mid Pro retains the user friendliness that the X-Mid tents are highly regarded for. Unlike most trekking pole tents, the rectangle based X-Mid has a simple 4 stake pitch with no mandatory guylines, no measuring or estimating odd angles, and no struts.

Once pitched, the intuitive minimalism continues with magnetic door toggles, doorways that aren’t blocked by poles, vestibules that put the main area beside the doorway instead of blocking it, a tensioned floor that lies taut and wrinkle free, and one handed operating zippers.

The X-Mid Pro also has a remarkably small packed size because of the efficient use of materials, less bulky floor material, and lack of struts which complicate packing up the tent.

Magnetic Toggles

Magnetic door toggles with pull tabs provide easy one handed-operation.

Doorways

Unlike most trekking pole tents, the doorways are large and not blocked by trekking poles.

Full Coverage Fly

The fly extends low to the ground to block drafts and rain splatter, yet can be raised for more ventilation. Other tents cut away the bottom of the fly to save weight but it leaves you more exposed.

Tensioned Floor

Small corner struts and cords tension the floor so it lays taut and easy to clean. Competing tents hang the bathtub floor from its top edge (like a bag) which saves weight but is more prone to wrinkling and sliding around.

Peak vents

Dual peak vents minimize condensation.

QUALITY

In addition to the highest performance design, the X-Mid Pro has industry leading quality. That starts by using premium materials like Dyneema, and assembling them at the most experienced tent factory in the world with Dyneema® fabrics.

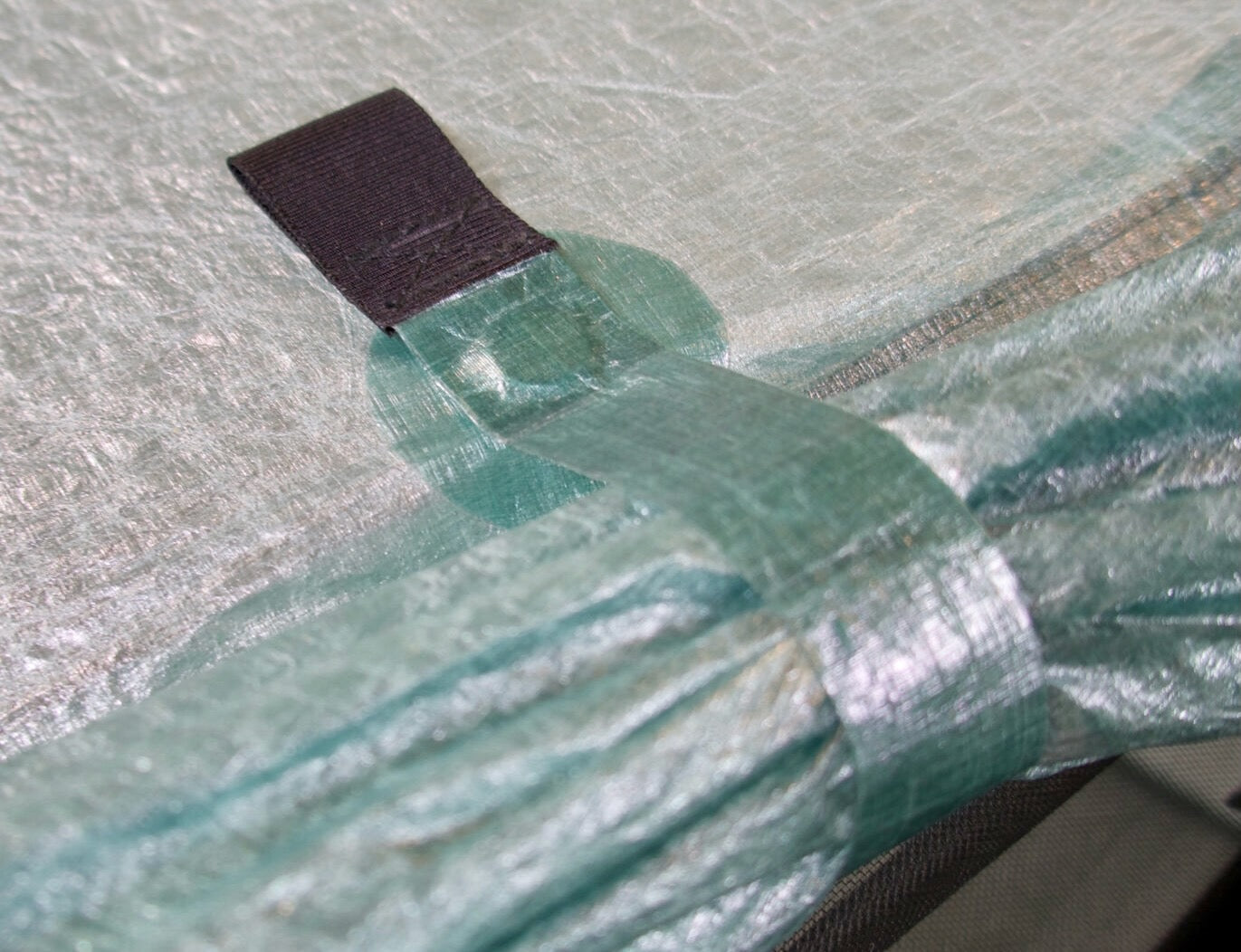

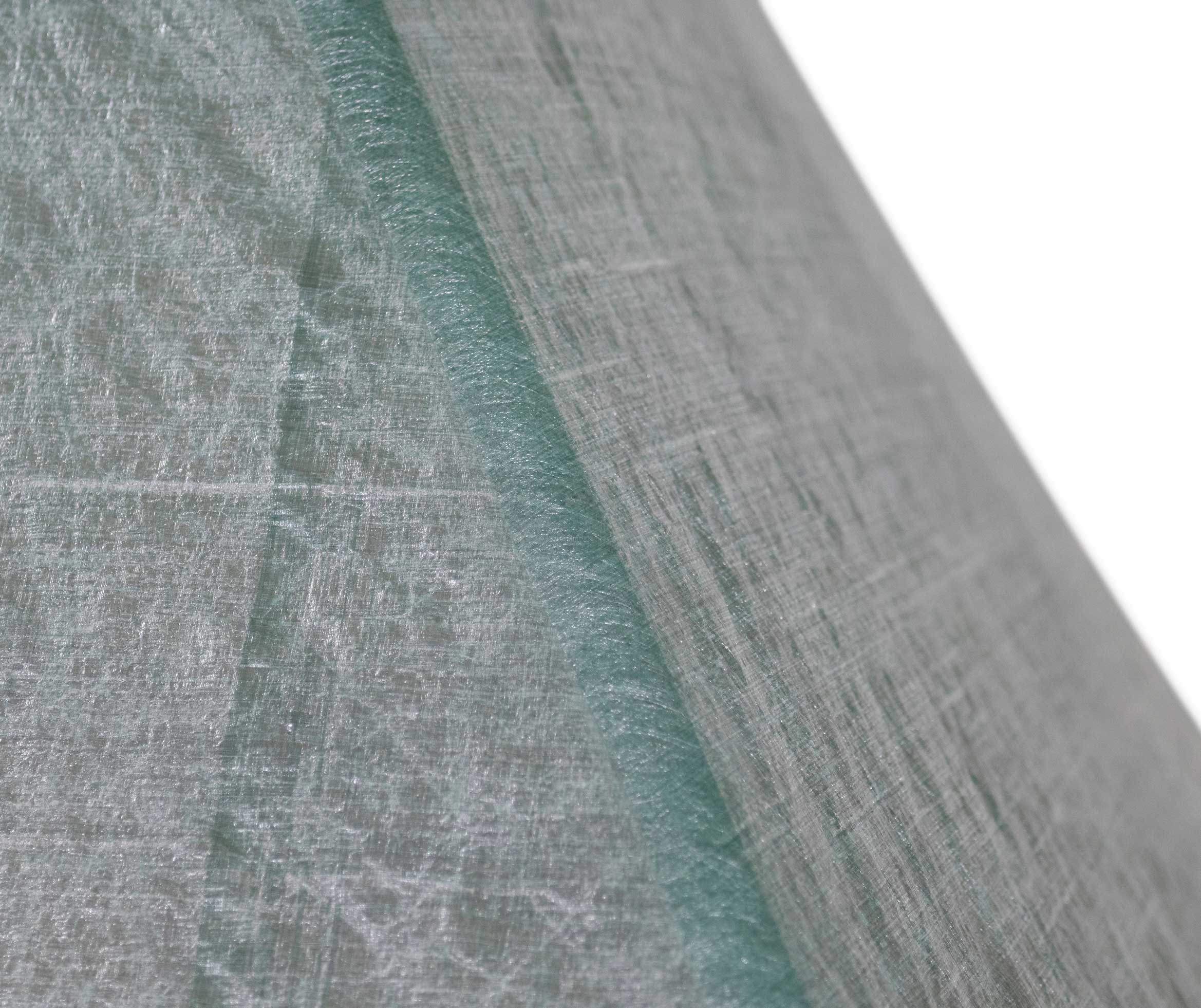

We use hot bonded construction to create seams that are stronger, cleaner looking, and better retain their strength in extreme temperatures. We also use a proprietary pre-shrinking process so that the shape is more stable over time and won't deform or shrink to create wavy zippers like other Dyneema® tents. Additionally, we use thoughtful design and reinforcements to avoid stressing the fabric diagonally (on the 'bias') which adds costs but prevents premature degradation.

PATENTED GEOMETRY

The X-Mid shape has been developed from the first principles of geometry to be as weight efficient, simple, and functional as possible.

That includes avoiding all the common pitfalls of trekking pole shelters such as a complicated pitch, mandatory guylines, poles blocking the doorways, and a lack of interior volume.

Read the story about how the X-Mid geometry was developed:

As one of the lightest tents in the world yet remarkably spacious and capable, the X-Mid Pro 2 is the ideal tent for everything from a thruhike of the Continental Divide Trail to bikepacking across South America.

Specifications

SPECIFICATIONS

Tent

17.9 oz / 509 g (Dyneema® floor) or 19.9 oz / 565 g (Silnylon floor)

Stuff Sack

0.3oz / 8g (Dyneema®) or 0.4 oz / 12 g (Silnylon)

Stakes (Optional)

DAC J Stakes (4 x 6" @ 7 g; 4 x 8" @ 16 g)

Typical Setup (Tent, Sack, 6 Stakes)

21.0 oz / 595 g (Dyneema® floor) or 23.1 oz (Silnylon floor).

Floor Length

90 in / 2.3 m

Floor Width

46 in / 1.17 m

Floor Area

28.75 sq ft / 2.7 sq m

Peak Height

46 in / 1.17 m

Fly Footprint

80 x 100 in / 2.03 x 2.54 m

Vestibule Area

23 sq ft (11.6 x 2) / 2 sq m (1 sq m x 2)

Packed Size

11 x 5 in / 27 x 12 cm

Canopy Fabric

Dyneema Composite Fabric 0.55 in Spruce Green

Floor Fabric

15D Sil/PEU nylon (grey) or Dyneema Composite Fabric 0.66 (white)

Fly Zippers

YKK #3 AquaGuard

Inner Zippers

YKK #3

Features

FEATURES

The weight efficient and patented X-Mid geometry combined with Dyneema® fabrics creates world's lightest two person tent, while also providing best in class headroom, living space, stormworthiness, and ease of pitching.

Dyneema® Composite Fabrics are extremely strong and highly waterproof (15,000mm).

Premium hot bonded construction provides stronger seams than cold taped or sewn construction.

A proprietary pre-shrinking process gives a Dyneema® shelter that doesn't deform over time or shrink to create wavy zippers.

We align all stress lines with the Dyneema fibers and/or add Dyneema® tape reinforcement so that the panels are never stressed diagonally (on the 'bias'). Other Dyneema® shelters often put major stress lines diagonally across the fabric to save costs but this deteriorates the material and shortens the tents lifespan.

Ultra-simple pitch with just four stakes, no measuring, and no odd angles. Competing tents require 6-10 stakes, sometimes mandatory struts and guylines, and measuring or estimating odd angles and pole heights.

Full coverage fly extends low to the ground to block drafts and rain splatter, but can also be pitched higher for more ventilation. Other tents trim away the bottom of the fly to save weight but this leaves you more exposed to rain splatter and drafts.

Dual magnetic door toggle system allows both the fly doors and inner doors to be quickly secured.

Optional peak and side panel guyouts plus up to 12 stakes can be used around the base for harsh conditions

Vestibules can be collapsed to fit into smaller tent sites

Dual doorways are zippered, not blocked by trekking poles, and keep rain off the floor even when open.

Dual vestibules are large, tall and put the main area beside the door instead of blocking it.

Dual adjustable peak vents minimize condensation yet can close during harsh conditions.

Dual interior pockets provide convenient storage.

Compare

COMPARE

The X-Mid Pro 2 provides unprecedented stormworthiness, user friendliness, and space for a superultralight tent, while also weighing less than all other 2P tents. To illustrate this, the table below compares the X-Mid Pro 2 to what is seen in competing tents.

X-Mid Pro 2

Main Competitors

Extends low to block drafts and splatter

High cut fly leaves you more exposed

Dual vents minimize condensation

Vents are small or omitted

4

6 - 10

No

Yes

Easiest

Medium - Hard

No

Yes

Smallest

25 - 50% larger

60 cu ft

45 - 56 cu ft

46" / 1.17 m

42 - 48" / 1.06 - 1.22 m

106" / 2.7 m

100" / 2.54 m

11.6 sq ft x 2

6 - 9 sq ft x 2

Beside doorway

Blocking doorway

17.9 oz / 509 g (DCF floor version)

18 - 24 oz / 511 - 680 g

19.3 oz / 549 g (DCF floor version)

20.6 - 26.8 oz / 590 - 760 g

FAQ

Our Dyneema® floors use Dyneema Composite Fabric 0.66 which has a thick outer layer only on the underside (where you need it) and not on the top side (where the regular thickness is sufficient) so that it offers similar durability to more common Dyneema Composite Fabric 0.96 floors while being lighter and packing smaller. We think this version is a better all around balance for an ultralight floor because it provides a good lifespan when used with care, while saving weight and reducing the packed size.

Compared to our 15D woven floor, we find durability is similar for the two floor options. Dyneema Composite Fabric 0.66 has an advantage in resisting tears while the woven floor has an advantage with abrasion but overall durability is quite similar. As such, the decision on which floor to choose mostly comes down to cost and weight. The Dyneema® floors come at a higher cost but enable an extra weight savings of about 2oz / 60g.

Aside from these main considerations, there are a few smaller considerations. A woven floor has the advantage of packing smaller yet and the silicone coating on the bottom can be re-applied in the future if needed, while a Dyneema® floor dries faster and is quieter. Both floors can be repaired with repair tape, but the repair tapes for Dyneema® are color matched to the material so they look better.

Overall, we recommend choosing the woven floor for the best value and smallest packed size, or choosing the Dyneema® floor for the absolute lowest weight and faster drying.

The X-Mid Pro uses the same YKK #3 zipper as almost all ultralight tents. These are a high quality zippers but since they are lightweight they do wear faster than a larger (heavier) zipper if there is prolonged use in sandy/dusty conditions, such as the PCT.

If your zippers do wear to the point of no longer closing properly, it is not actually a major problem but rather is usually just a worn out slider, which we are happy to replace for free and also is easy to replace yourself on the trail (by making a small incision at the top and swapping the slider). If your zippers do need servicing like this, please email us and we can provide instructions. Replacing the sliders will restore new performance as long as the teeth aren't damaged from a high force accident such as tripping over the tent.

To reduce the rate of wear and get maximum life out of your sliders, it is helpful to stake out the door at an angle to take tension off the zipper (see pitching video), and also to clean the zipper with a brush if there is sand/grit caught in the teeth because dirt in the teeth will accelerate wear.

The floor width of the X-Mid Pro 2 will vary depending on how high it is pitched. With a low pitch the floor will be wider and can fit two wide (25") tapered pads by placing them opposite ways, or placing them side by side and splaying out the walls a bit.

However, our larger X-Mid Pro 2+ provides those extra inches of width that are needed to easily fit all wide pads including two wide rectangular pads. If you plan to regularly use two wide pads we recommend the X-Mid Pro 2+ model.

No. We recommend that two people sleep the same way. The sleeping area is a bit different on each side, but the tent is quite spacious with 20-35% more interior volume than its main competitors, so two people can sleep the same way.

Compared to most trekking pole tents, the X-Mid’s diagonal ridgeline gives additional headroom in the tent. This extra headroom is gained diagonally, so two opposite corners get outstanding headroom, while the other two corners have more regular head room. You could sleep opposite so both people get extra head clearance, but when sleeping the same way the person on the regular side still has as much head clearance than competing tents.

With that said, if you are worried about this our larger X-Mid Pro 2+ model is further optimized for sleeping two people in the same direction since it is wider, taller, and has less rotation on the ridgeline for more even headroom on both sides.

The X-Mid tents do have a unique floorplan where two opposite corners are lower and intended for gear storage. For the best results, the person with a low corner at their head should move down to leave this low corner as a space for gear and improve their head clearance. This works great because it puts both sleepers in a normal side by side position with gear storage at two opposite corners.

A singlewall tent is when the floor of the tent is sewn to the fly so the canopy has just one layer instead of having a second inner layer of bug mesh or fabric. The X-Mid Pro is singlewall in some parts (ends, roof) but still doublewall in other areas (sides) so it can be called a hybrid tent.

The design is 100% bug proof and brings substantial weight savings. The downsides are that you don’t have the ability to use the fly and inner separately, and that there aren’t mesh inner walls in all areas to prevent you from touching the fly if there is condensation.

The X-Mid Pro 2 has every possible advantage to minimize condensation (e.g. large peak vents, spacious) and it is not more prone to condensation than other tents, but if condensation does occur you do need to be more careful not to touch it. The X-Mid Pro makes this easier than most single wall tents because it is more spacious, has mesh walls on both sides, and has steep end walls to avoid contact.

The X-Mid Pro 2 has a length inside the fly that is 6″ longer than it’s main competitors because the fly length is similar but in the X-Mid Pro you sleep on a 20 degree angle to the fly so the length inside the fly is 106″. The floor is still 90″ but this longer fly gives headroom and clearance at both ends.

When sleeping two people in the tent we recommend it up to 6’4″. That is a realistic estimate of what we think 90% of people would agree with (not some inflated marketing answer) but the actual outcome varies depending on several factors including how thick your pad is, if you use a pillow, how large your sleeping bag is, how straight you sleep (e.g. side vs back sleepers), and how much space you think is enough. If you have a bulky setup and want a lot of extra room you might only find it suitable to 6’0″ whereas if you have a compact setup and aren’t too fussy it can work to 6’6″+. We recommend sleeping in the same direction, but note that the headwall will be steeper for one person than the other, so if one person is taller we recommend they sleep on the steeper headwall side for a bit more clearance at their head end. If you are considering using this tent solo, the parallelogram floor gives one diagonal that is very long and we think it works well for up to 7’0″.

If you want even more space, our X-Mid Pro 2+ is an even larger tent including steeper end walls for a few more inches of useable length.

Our 15D silnylon and Dyneema® floor options are similar in durability. Both have been selected as a balance between lightweight and durability, where we select the lightest material that we still think is okay to use without a groundsheet (provided it is used with care and not on unusually harsh surfaces like gravel).

As such, we say a groundsheet is not required but about 50% of users prefer to have one as added protection and/or to keep their floor cleaner. We do offer optional groundsheets and recommend them for users who wanted added protection, don't want to check their sites for sharp objects, and/or who camp on harsher surfaces like rock.

The X-Mid geometry is the most volumetrically efficient shape possible. Thus, it is impossible to design a lighter tent unless you use lighter materials, cut features, or make it smaller.

With the X-Mid Pro we have combined the X-Mid geometry with Dyneema® fabrics to create one of the world's lightest 2P tents. There are only a few tents that are slightly lighter and these design achieve that by making it smaller, less durable, and less functional. For the size and level of protection, there is nothing lighter.